Diesel Flow Meter

- Accurately measures diesel fuel flow

- High-precision turbine sensor

- Large digital display for easy reading

- Durable, corrosion-resistant design

- Simple installation and integration.

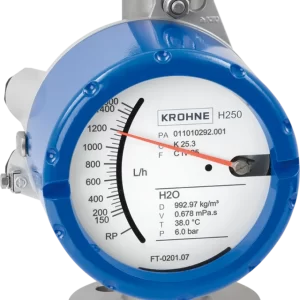

The Diesel Flow Meter is a device used to accurately measure the flow rate of diesel fuel in industrial applications, such as transportation, construction, or power generation. It features a high-precision turbine sensor that detects the fluid flow and converts it into a measurable electrical signal.

The device has a large, easy-to-read digital display that shows the flow rate and total amount of fuel dispensed. The meter has a durable and corrosion-resistant body, making it suitable for harsh industrial environments.

The device is simple to install, with a compact design that allows easy integration into existing fuel dispensing systems. It is compatible with multiple diesel fuels, including low-viscosity fuels, and has a wide measurement range that can accommodate different flow rates.

The Diesel Flow Meter provides reliable and accurate measurement data, making it an essential tool for controlling fuel costs and improving operational efficiency in various industries.

Features of Diesel Flow Meter

- The Diesel Flow Meter features a high-precision turbine sensor that accurately measures the flow rate of diesel fuel.

- It has a large, easy-to-read digital display that shows the flow rate and total amount of fuel dispensed.

- The device is designed with a durable and corrosion-resistant body, making it suitable for use in harsh industrial environments.

- The meter is simple to install, with a compact design that allows easy integration into existing fuel dispensing systems.

- It is compatible with various diesel fuels, including low-viscosity fuels, and has a wide measurement range.

- The Diesel Flow Meter provides reliable and accurate measurement data, making it an essential tool for controlling fuel costs and improving operational efficiency in various industries.

Where to Diesel Flow Meter

If you want a Diesel Flow Meter, you can check out ICS Pakistan. ICS is a leading supplier of industrial equipment and is known for offering high-quality products at competitive prices. They have a wide range of diesel flow meters available, and their knowledgeable staff can help you find the right device for your needs. Whether you are in the transportation, construction, or power generation industry, ICS is the place to go for reliable and cost-effective solutions.