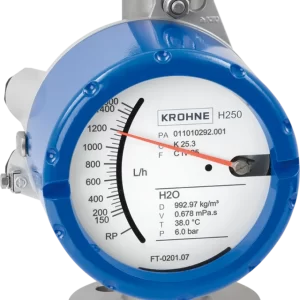

Hot Water Turbine Flow Meter

- Measures hot water flow accurately.

- High-temperature tolerance.

- Compact and durable design.

- Clear digital display. Easy installation and maintenance.

The Hot Water Turbine Flow Meter is a highly accurate and reliable device designed to measure the flow rate of hot water in industrial, commercial, and residential applications. This meter features a compact design and high-quality materials to ensure durability and longevity in even the harshest conditions.

With its high-temperature tolerance, the Hot Water Turbine Flow Meter is perfect for hot water systems such as boilers, solar heating, and geothermal systems. The meter’s turbine design allows it to accurately measure even low flow rates, making it ideal for energy management and conservation efforts.

The Hot Water Turbine Flow Meter is easy to install and requires minimal maintenance. It features a digital display that provides clear and accurate readings and is compatible with various output options, including pulse, 4-20mA, and RS485. The meter also has a built-in temperature compensation function to ensure accurate readings regardless of temperature changes.

Whether you are monitoring the flow rate of hot water for energy management, system optimization, or safety reasons, the Hot Water Turbine Flow Meter is an excellent choice. With its accuracy, reliability, and ease of use, this device is the ideal solution for measuring hot water flow in many applications.

Features of Hot Water Turbine Flow Meter

- The Hot Water Turbine Flow Meter provides accurate and reliable measurements of hot water flow, ensuring the most precise results.

- With its high-quality materials, this meter is built to endure even the harshest conditions.

- The compact design of the Hot Water Turbine Flow Meter makes it easy to install and integrate into your hot water system.

- With minimal maintenance requirements, this meter is low-hassle and cost-effective over its lifespan.

- A clear and easy-to-read digital display provides accurate readings, ensuring that you always know the flow rate of your hot water system.

- The Hot Water Turbine Flow Meter has a built-in temperature compensation function, providing accurate readings regardless of temperature fluctuations.

Where to Buy Hot Water Turbine Flow Meter

The Hot Water Turbine Flow Meter is from ICS Pakistan, a trusted, high-quality flow measurement equipment provider. ICS Pakistan is the best place to buy if you’re in the market for a reliable and accurate hot water flow meter. With their extensive selection of flow meters, you’re sure to find the suitable device for your specific needs.