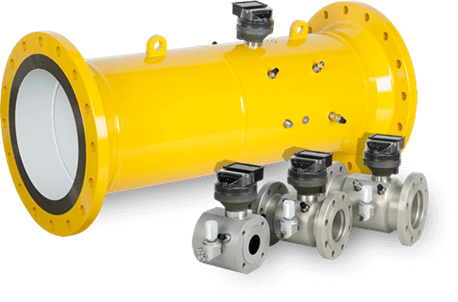

Natural Gas Turbine Flow Meter

- Spinning turbine wheel measurement

- Accurate and reliable readings

- Durable for harsh conditions

- Easy installation and maintenance

- Widely used in industrial/commercial applications.

The Natural Gas Turbine Flow Meter is a highly accurate and reliable tool used to measure the flow of natural gas in pipelines. The device operates on the principle of a spinning turbine wheel, which is positioned within the pipeline to measure the velocity of the gas flow. The velocity reading is then converted into a flow rate measurement, which can be used for multiple purposes such as monitoring, controlling, and billing.

This flow meter is commonly used in various industrial and commercial applications, including power plants, natural gas processing plants, and distribution networks. It is designed to be durable, easy to install, and maintain, making it an ideal choice for any natural gas pipeline application.

The device is built with high-quality materials to withstand harsh conditions, including extreme temperatures and high pressure. Even in challenging flow conditions, the flow meter provides accurate and consistent readings with advanced sensing technology.

One of the main advantages of the Natural Gas Turbine Flow Meter is its ease of installation and maintenance.

Features of Natural Gas Turbine Flow Meter

- The Natural Gas Turbine Flow Meter operates on the principle of a spinning turbine wheel to measure the velocity of natural gas flow.

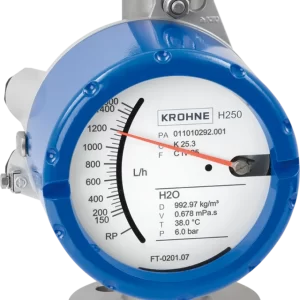

- It is highly accurate and reliable, providing consistent and precise flow rate measurements.

- The device is designed to be durable and withstand harsh conditions, including extreme temperatures and high pressure.

- It is easy to install and maintain, with minimal maintenance requirements to keep ownership costs low.

- Advanced sensing technology provides accurate readings even in challenging flow conditions.

- The flow meter is widely used in industrial and commercial applications, such as power plants, natural gas processing plants, and distribution networks.

Where to Buy Natural Gas Turbine Flow Meter

If you are in the market for a Natural Gas Turbine Flow Meter, ICS Pakistan is a great place to start your search. ICS Pakistan is a well-established supplier of high-quality industrial equipment, including the Natural Gas Turbine Flow Meter.